The Science Behind Polyaspartic Coatings: A Complete Guide for Florida Property Owners

- Revelry Coatings

- Jul 9

- 7 min read

Updated: Aug 2

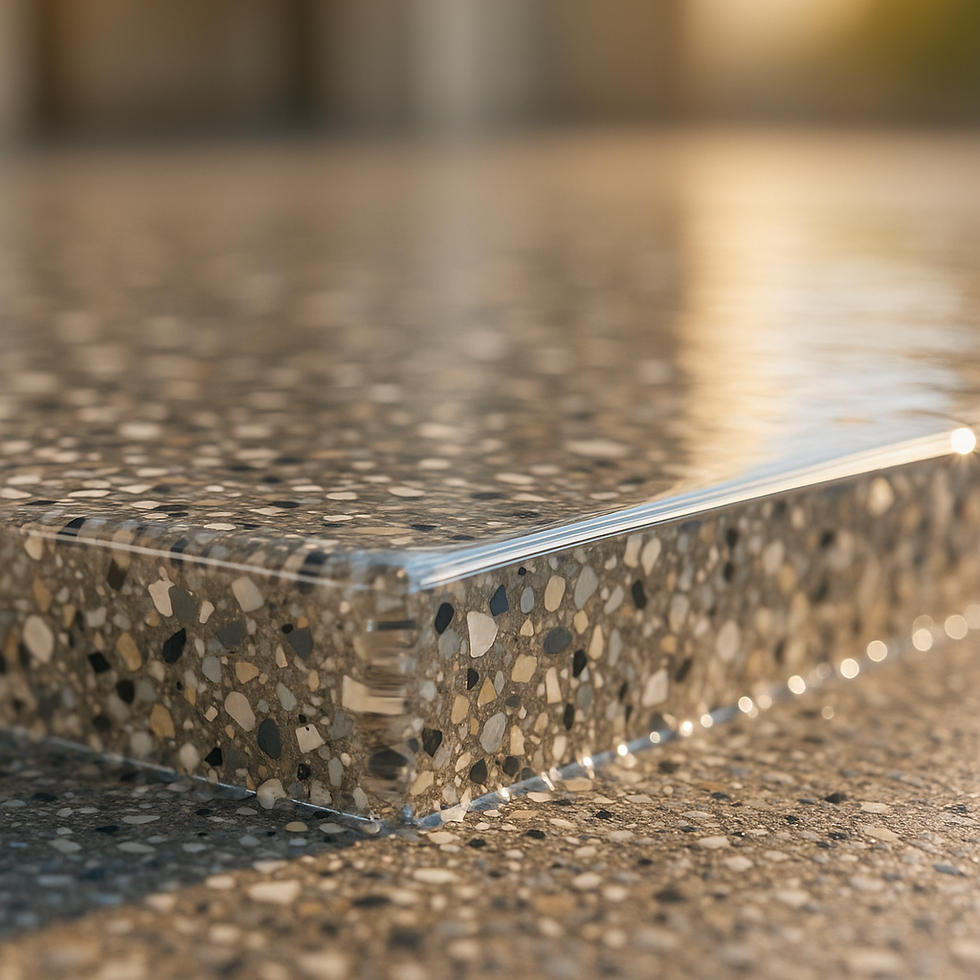

Transform your concrete surfaces with cutting-edge polyaspartic technology designed specifically for Florida's unique climate

Florida's intense heat, humidity, and frequent storms create some of the most challenging conditions for concrete coatings in the United States. Traditional epoxy coatings often fail within just a few years, leaving property owners frustrated with peeling, yellowing, and degraded surfaces. Enter polyaspartic coatings—a revolutionary technology that's changing the game for Florida homeowners and businesses across Orlando, Melbourne, Winter Park, and beyond.

At Revelry Coatings, we've witnessed firsthand how polyaspartic technology transforms concrete surfaces while standing up to Florida's harshest environmental conditions. This comprehensive guide explores the science behind polyaspartic coatings and why they're the optimal choice for property owners throughout Central Florida.

What Are Polyaspartic Coatings? Understanding the Technology

Polyaspartic coatings represent a breakthrough in protective concrete technology. Unlike traditional epoxy systems, polyaspartic coatings are aliphatic polyurea formulations that cure through a chemical reaction between a polyaspartic ester and an aliphatic polyisocyanate. This unique chemistry creates a coating that's fundamentally different from anything that came before.

The term "polyaspartic" comes from the polyaspartic ester component, which was originally developed by Bayer in the 1990s. These esters provide the coating with exceptional clarity, UV stability, and chemical resistance—properties that make them ideal for Florida's demanding environment.

Key Chemical Properties

Aliphatic Structure: The aliphatic backbone of polyaspartic coatings provides superior UV resistance compared to aromatic coatings like traditional epoxy. This means your floors won't yellow or chalk under Florida's intense sunlight.

Cross-Link Density: Polyaspartic coatings form an extremely dense cross-linked network as they cure, creating a surface that's harder and more durable than concrete itself.

Molecular Flexibility: Despite their hardness, polyaspartic coatings maintain molecular flexibility, allowing them to expand and contract with concrete substrates without cracking.

Why Florida's Climate Demands Polyaspartic Technology

The Challenge of Florida's Environment

Florida presents unique challenges for concrete coatings:

High Humidity: Consistent humidity levels above 70% can cause traditional coatings to fail

UV Exposure: Intense year-round sunlight degrades most coating systems

Temperature Fluctuations: Rapid temperature changes cause expansion and contraction

Moisture Vapor Transmission: High water tables and frequent rain create moisture pressure beneath slabs

Salt Exposure: Coastal areas and pool chemicals accelerate coating degradation

How Polyaspartic Coatings Overcome These Challenges

Moisture Tolerance: Polyaspartic coatings can be applied in humidity up to 85% without compromising adhesion or cure quality. The chemical cure mechanism isn't hindered by moisture like traditional coatings.

UV Stability: The aliphatic chemistry provides exceptional UV resistance, maintaining color and gloss even after years of Florida sun exposure. Independent testing shows polyaspartic coatings retain 87-89% of their original gloss after 1,000 hours of UV exposure.

Rapid Cure: Fast cure times (as quick as 4-6 hours for foot traffic) mean applications can be completed between weather events, reducing the risk of contamination from sudden storms.

Chemical Resistance: Superior resistance to pool chemicals, automotive fluids, and household cleaners makes polyaspartic coatings ideal for Florida homes and businesses.

The Science of Simiron Polyaspartic HS: Premium Performance

At Revelry Coatings, we exclusively use Simiron Polyaspartic HS systems—the gold standard in polyaspartic technology. Here's what makes this system exceptional:

Advanced Formulation Features

High Solids Content: At 90-93% solids by volume, Simiron Polyaspartic HS provides exceptional build and coverage while minimizing volatile organic compounds (VOCs).

Variable Cure Speeds: Available in XTRA Slow, Slow, Medium, and Fast cure formulations, allowing optimal application in any Florida weather condition.

Thick Build Capability: Can be applied up to 16 mils thick in a single pass, perfect for full-flake broadcast systems.

1:1 Mix Ratio: Simplifies application and reduces the chance of mixing errors that can compromise performance.

Performance Characteristics

Tensile Strength: 4,000 PSI—stronger than most concrete substrates

Shore D Hardness: 86 (fully cured)—extremely durable surface

Abrasion Resistance: Only 30mg loss in 1,000-cycle Taber testing

Coefficient of Friction: 0.63 (wet) over full flake systems—excellent slip resistance

The Polyaspartic Full Flake System: Engineered for Florida

System Architecture

The optimal polyaspartic system for Florida consists of three critical components:

Primer/Base Coat: Moisture-mitigating primer that bonds to concrete and prevents vapor transmission

Full Flake Broadcast: 100% coverage with decorative polymer flakes for texture and aesthetics

Polyaspartic Topcoat: High-solids clear coat that seals and protects the system

Why Full Flake Systems Excel in Florida

Moisture Management: The full flake layer creates a barrier that prevents moisture from reaching the topcoat, eliminating bubbling and delamination.

Thermal Expansion: The flexible flake layer accommodates thermal movement without cracking.

Slip Resistance: Provides excellent traction even when wet—crucial for Florida's frequent rain.

Aesthetic Versatility: Available in dozens of color combinations to match any design preference.

Installation Science: Precision Application for Maximum Performance

Surface Preparation: The Foundation of Success

Concrete Surface Profile (CSP): Diamond grinding to achieve CSP 1-3 ensures optimal mechanical bond Moisture Testing: ASTM F1869 and F2170 testing ensures moisture levels are within acceptable limits Crack Repair: Proper crack treatment prevents telegraphing through the coating system

Environmental Considerations

Temperature: Optimal application between 60-85°F for consistent cure Humidity: Can be applied up to 85% relative humidity Dew Point: Application suspended when surface temperature is within 5°F of dew point

Application Techniques

Squeegee and Backroll: Ensures even film thickness and complete coverage Wet Edge Maintenance: Critical for eliminating visible lap marks Timing: Precise timing between coats ensures proper intercoat adhesion

Performance Testing: Proven Results in Florida Conditions

Laboratory Testing Results

UV Resistance: ASTM G154 testing shows minimal gloss loss after 1,000 hours Chemical Resistance: Excellent to good resistance against 30+ common chemicals Thermal Cycling: No cracking or delamination after 50 freeze-thaw cycles Abrasion Resistance: Superior performance compared to epoxy and urethane systems

Real-World Florida Performance

Independent testing in Florida conditions shows:

Color Retention: 95%+ after 5 years of sun exposure

Adhesion: No delamination after 3 years in high-humidity environments

Chemical Resistance: No staining from pool chemicals, automotive fluids, or household cleaners

Service Areas: Bringing Advanced Technology to Central Florida

Revelry Coatings proudly serves property owners throughout Central Florida, including:

Orlando Metro: Orlando, Winter Park, College Park, Dr. Phillips, Bay Hill, Windermere Space Coast: Melbourne, Viera, Cocoa, Cocoa Beach, Cape Canaveral, Titusville East Orlando: Avalon Park, Alafaya, Waterford Lakes, Corner Lakes West Orange: Horizon West, Clermont, Winter Haven

Each location presents unique challenges, from the coastal salt air in Cocoa Beach to the tourist traffic in Orlando's attractions district. Our team understands these local conditions and tailors each installation accordingly.

Applications: Where Polyaspartic Coatings Excel

Residential Applications

Garage Floors: Transform your garage into a showroom-quality space that resists oil stains, tire marks, and chemical spills. The rapid cure time means you can park your car the same day.

Patios and Pool Decks: UV-stable polyaspartic coatings maintain their appearance under Florida's intense sun while providing slip-resistant surfaces around pools.

Driveways: Enhance curb appeal while protecting against automotive fluids and UV degradation.

Commercial Applications

Restaurants and Bars: Food-safe coatings that resist grease, acids, and frequent cleaning Auto Service Centers: Chemical-resistant surfaces that handle hydraulic fluids, oils, and heavy traffic Retail Spaces: High-gloss finishes that enhance lighting and create professional appearances Warehouses: Durable floors that resist forklift traffic and chemical spills

The Economic Advantage: Long-Term Value

Initial Investment vs. Lifetime Value

While polyaspartic coatings require a higher initial investment than traditional epoxy, the long-term economics are compelling:

Longevity: 15-20 year lifespan vs. 3-5 years for epoxy

Maintenance: Minimal maintenance requirements reduce ongoing costs

Downtime: Same-day cure eliminates lost productivity

Property Value: Professional-grade floors add significant resale value

Cost of Failure

Traditional coatings that fail in Florida's climate require:

Complete removal and reapplication

Business interruption

Potential concrete damage from failed coatings

Lost aesthetic appeal

Environmental Benefits: Sustainable Technology

Simiron Polyaspartic HS contains less than 50 g/L VOCs, making it:

LEED Compliant: Contributes to green building certifications

Indoor Air Quality: Safe for enclosed spaces

Environmental Responsibility: Minimal impact on air quality

Longevity Benefits

Longer-lasting coatings reduce:

Material consumption over time

Waste generation from failed coatings

Energy consumption from frequent reapplication

Quality Assurance: The Revelry Coatings Difference

Our installers are:

Factory-trained on Simiron products

Certified in proper surface preparation techniques

Experienced in Florida's unique conditions

Committed to following manufacturer specifications

Comprehensive Warranty

We stand behind our work with:

Material Warranty: Direct manufacturer support

Installation Warranty: Comprehensive coverage of our workmanship

Performance Guarantee: Confidence in long-term results

Maintenance: Keeping Your Investment Beautiful

Routine Maintenance

Daily Care: Sweep and damp mop with mild cleaners Weekly Deep Clean: Use approved concrete cleaners for heavy soiling Annual Inspection: Professional assessment of coating condition

Long-Term Care

Avoid Harsh Chemicals: Use only approved cleaning products Protect from Damage: Use furniture pads and avoid dragging heavy objects Professional Maintenance: Periodic professional cleaning and inspection

The Future of Concrete Coatings in Florida

Emerging Technologies

The coating industry continues to evolve with:

Smart Coatings: Self-healing and self-cleaning technologies

Enhanced UV Protection: Even greater durability against Florida's sun

Sustainable Formulations: Bio-based polyaspartic systems

Market Trends

Florida property owners increasingly recognize:

Value of Quality: Preference for long-term solutions over cheap alternatives

Aesthetic Importance: Decorative coatings that enhance property value

Environmental Consciousness: Low-VOC, sustainable options

Transform Your Property with Proven Science

The science behind polyaspartic coatings represents decades of chemical engineering advancement specifically designed to overcome the challenges facing concrete surfaces in demanding environments. For Florida property owners, this technology offers unprecedented durability, aesthetic appeal, and long-term value.

At Revelry Coatings, we're proud to bring this advanced technology to communities throughout Central Florida. Our commitment to using only the highest-quality Simiron Polyaspartic HS systems, combined with our expertise in Florida's unique conditions, ensures that your investment will provide years of beautiful, durable performance.

Whether you're looking to transform your garage in Orlando, upgrade your pool deck in Melbourne, or enhance your commercial space in Winter Park, polyaspartic coatings offer the perfect solution. The science is proven, the results are exceptional, and the value is undeniable.

Ready to experience the difference that advanced polyaspartic technology can make for your property? Contact Revelry Coatings today for a free consultation and discover why Florida property owners are choosing polyaspartic coatings for their most important concrete surfaces.

Revelry Coatings is your trusted partner for premium polyaspartic coating systems throughout Central Florida. With locations serving Orlando, Melbourne, Winter Park, and surrounding communities, we bring professional-grade concrete transformation to your doorstep. Contact us today to schedule your free estimate and join the thousands of satisfied customers who have discovered the Revelry Coatings difference.

Comments